Manufacturing Process

Jyoti Capsulation has a world-class manufacturing and analysis facility in its factory premises. Our facility meets the cGMP standards besides other standards prescribed under the Drugs and Cosmetics Act and Rules. It strictly follows guidelines laid down by the W.H.O. for the manufacturing of Pharmaceutical Formulations.

The manufacturing plant at the site is solely dedicated for the production of those pharmaceutical formulations for which due permission has been obtained from the Licensing Authorities.

Formulation

We use raw materials after passing them through specified tests by our Quality Control Department, as per pharmacopoeia and as per In-house specifications.

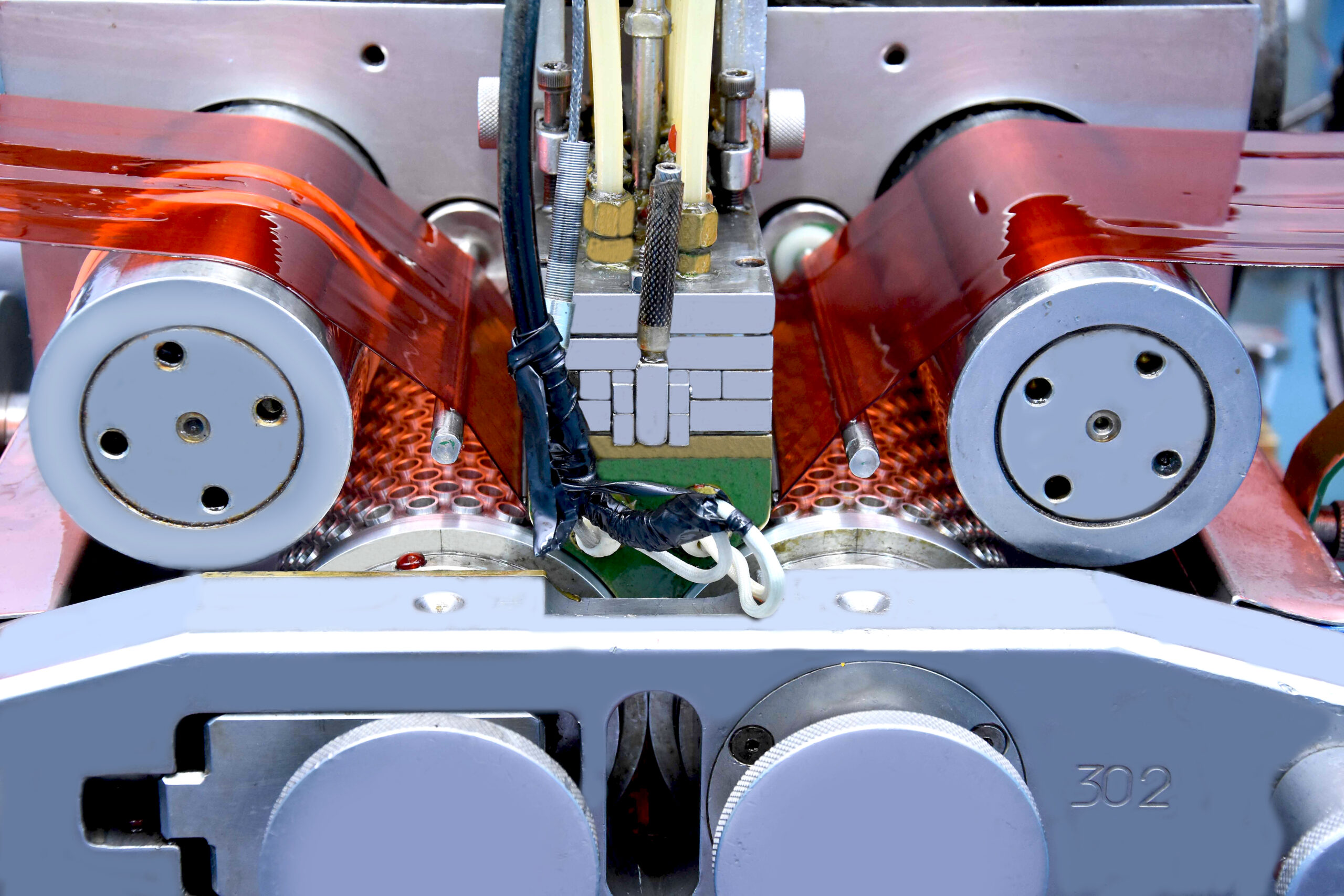

Soft gelatin capsules are manufactured in the room where environmental conditions, like temperature and humidity, are controlled and monitored by special devices. Rotary Die encapsulation machines are used for manufacturing of soft gelatin capsules. During encapsulation, capsules are checked for their size, shape, and leakage and weight variation by manufacturing chemist as well as by IPQC.

We have 6 Deoiling Machines and 3 Drying Chambers. Encapsulated capsules first undergo the Deoiling process and then the drying process under controlled environmental conditions.

Packaging

At Jyoti Capsulation, we provide durable, transparent, and tamper proof packaging. Our facility allows Soft Gelatin Capsules to be packed either in blisters or in bottles. We have various options in blister and bottle packaging. Bottle fillings are provided with tamper evident caps and freshness seals to prolong shelf life.

Additionally, automatic labelling can be applied to the bottles. Re-labelling can also be provided for language differences with some imported products.

Quality Control Department

We have a dedicated Quality Control Lab with Microbiology Department to carry out testing as per specifications and standards. All specifications and analytical methods are approved by Quality Control Department and Quality Assurance Department. The Analytical skills of our experienced and qualified analysts are supported by Sophisticated Analytical Instruments such as UV Visible Spectrophotometer, Disintegration Test Apparatus, Gas Chromatography, Polarimeter, UV cabinet, Laminar Flow Station, BOD Incubator, Dissolution Test Apparatus, High Performance Liquid Chromatography (HPLC), Karl Fischer Titrator, pH meter, Refractometer, Incubators Vacuum Ovens Sterility Test Unit.

Quality Assurance Department

We strive to provide customers with quality products that exceed their expectations. We achieve this through our Quality Assurance program developed to ensure continuous validation and improvement in all areas of the manufacturing process. The depth of experience, capabilities, knowledge of our technical professionals and the advanced scientific analytical instruments assures that a world class quality of final product reaches our customers.

Arrangement for Water Treatment

We have a Water softener plant for our chiller plant, Deioniser with the capacity of (60 Litre/ Hour) and Water Treatment Plant (R.O. System) for manufacturing.

The reverse osmosis process uses semi permeable spiral wound membranes to separate and remove dissolved solids, organic, pyrogens, sub micron colloidal matter and bacteria from water.

Feed water is delivered under a specified pressure through reverse osmosis membranes and is delivered as purified water.

Jyoti Capsualtions Pvt Ltd.

The Company has been also manufacturing various pharmaceutical products for other esteemed Pharmaceutical Companies under Loan Licenses/ Third Party Agreement. Over the last decade, we have systematically strengthened our capabilities in understanding and aligning ourselves. “Jyoti Capsulation was granted WHO CGMP certification in the year 2009”

Quick Links

Get in touch

Address

123/37 Saresh Bagh, Factory Area, Kanpur – 208012 U.P. (India)

Ph No. +919956335559

jcpl@jyoticapsule.com